Navigating through change successfully can mean the difference between survival and extinction. In today’s current situation organisations need to learn how to navigate through change and fail fast and learn from it. Some ideas that can come to mind when hearing the concept of change are upgrading technologies and systems,... read more →

One of the big challenges in organisations today, is engaging the people to contribute to improving their own workplace. Gallup produced a report in 2017 highlighting that 85% of employees worldwide are not engaged or actively disengaged in their jobs. It has also indicated that 69% of the people said... read more →

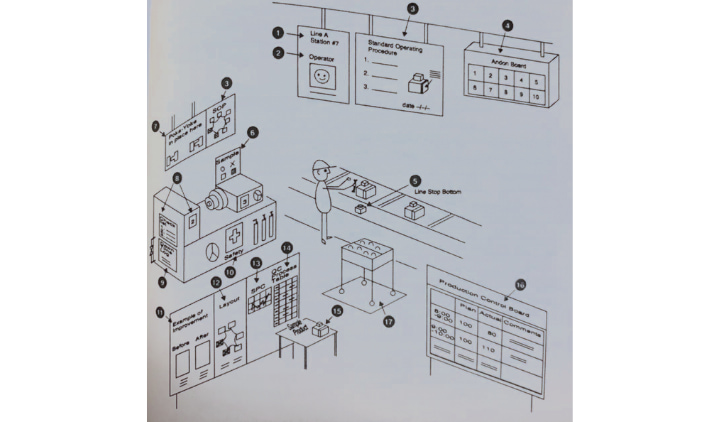

This concept capitalises on visual ability; where by making things viewable they become understandable, and therefore enforceable in the workplace. The purpose of visualisation is to distinguish good conditions from bad conditions, and to move quickly into action. Visualisation also helps create a workplace environment where new employees can also understand... read more →

Kaizen at Toyota develops a mental framework for individuals. Kaizen leadership raises employee’s problem awareness, as they identify where the system falls short of perfection, and constantly seek solving problems, or improving the process every day (Ballé, 2006; Spear, 1999). When carrying out kaizen activities the focus should not be... read more →

Spear and Bowen (1999) explain how TPS creates a community of scientists as the system enables establishing sets of hypotheses when defining specifications and then testing them. The system drives people at all levels (shop floor workers, team leaders, managers, etc) to get involved in experiments that are recognised as... read more →

Mistake 1: No Vision & No Strategy The starting point for any initiative must be a clear vision of what we want to achieve and where we want to be in the future. Organisations that lack a clear vision will not be able to set goals... read more →

Have you ever thought about What triggers ideas, or "Why do we seek change?". This article will help increase generating kaizen ideas for leaders. The need for change and triggering ideas are happening because of 2 simple reasons. The first reason is the brain identifies a problem so it triggers the need for change to... read more →

When establishing a kaizen culture, it is essential that top management provide their employees with the initiatives behind it and why it is required. Management must also provide employees with the resources they need. Examples of the resources can be time, material, tools, training, support, and/or coaching. A team leader’s... read more →

Kaizen culture emerges as a result of peoples’ intelligence and energy. It is important to set in place systems to develop people who challenge, think, and continuously improve processes and products. At Toyota, the system is built around people who are deeply involved in the Toyota way (Liker & Morgan,... read more →

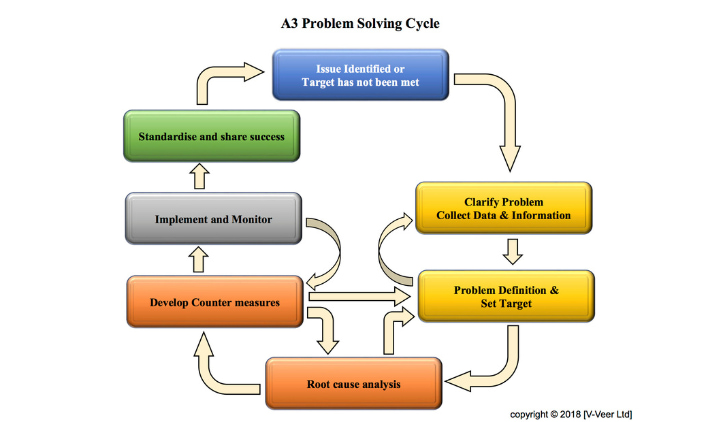

The A3 problem solving is one of the most used lean tools out there today. But, unfortunately it is also one of the most misused, too. The aim of the A3 at Toyota, based on literature and the many advocates of TPS, is to have a strong structured way to... read more →