What is Kaizen?

Kaizen is a Japanese compound word that is a combination of ‘Kai’ (change) and ‘Zen’ (to the better). The term Kaizen is translated into continuous improvement in English. Kaizen should involve everyone and applied everywhere everyday.

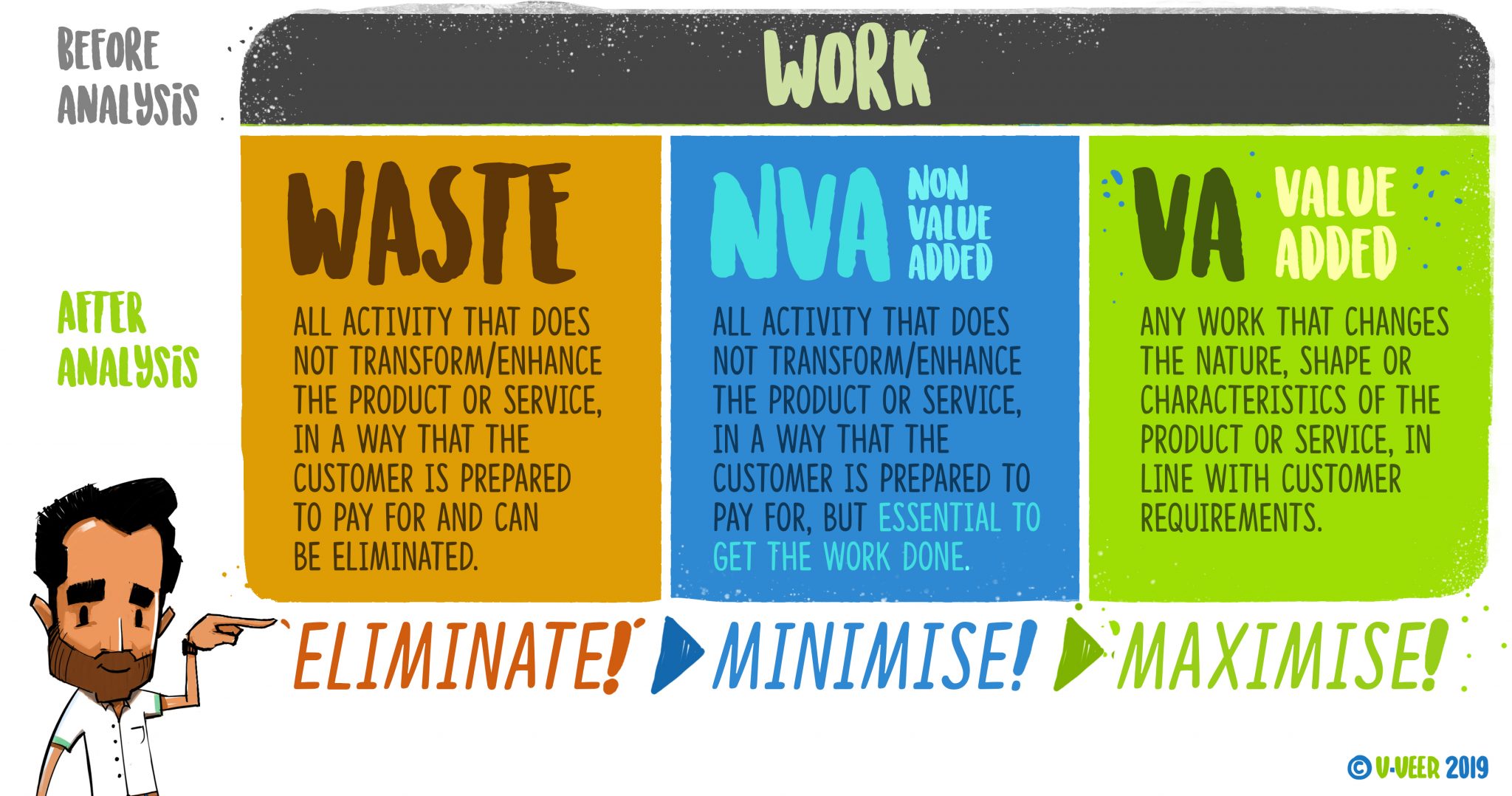

Value Added, Non Value Added & Waste

Any activity can be categorized into one of three types Value Added, Non Value Added, or Waste from a customer point of view.

Who is the customer?

There are two types of customers: external customer and internal customer. External customers are the people who buy our products or services. Internal customers are people or departments who receive a service or a product from you.

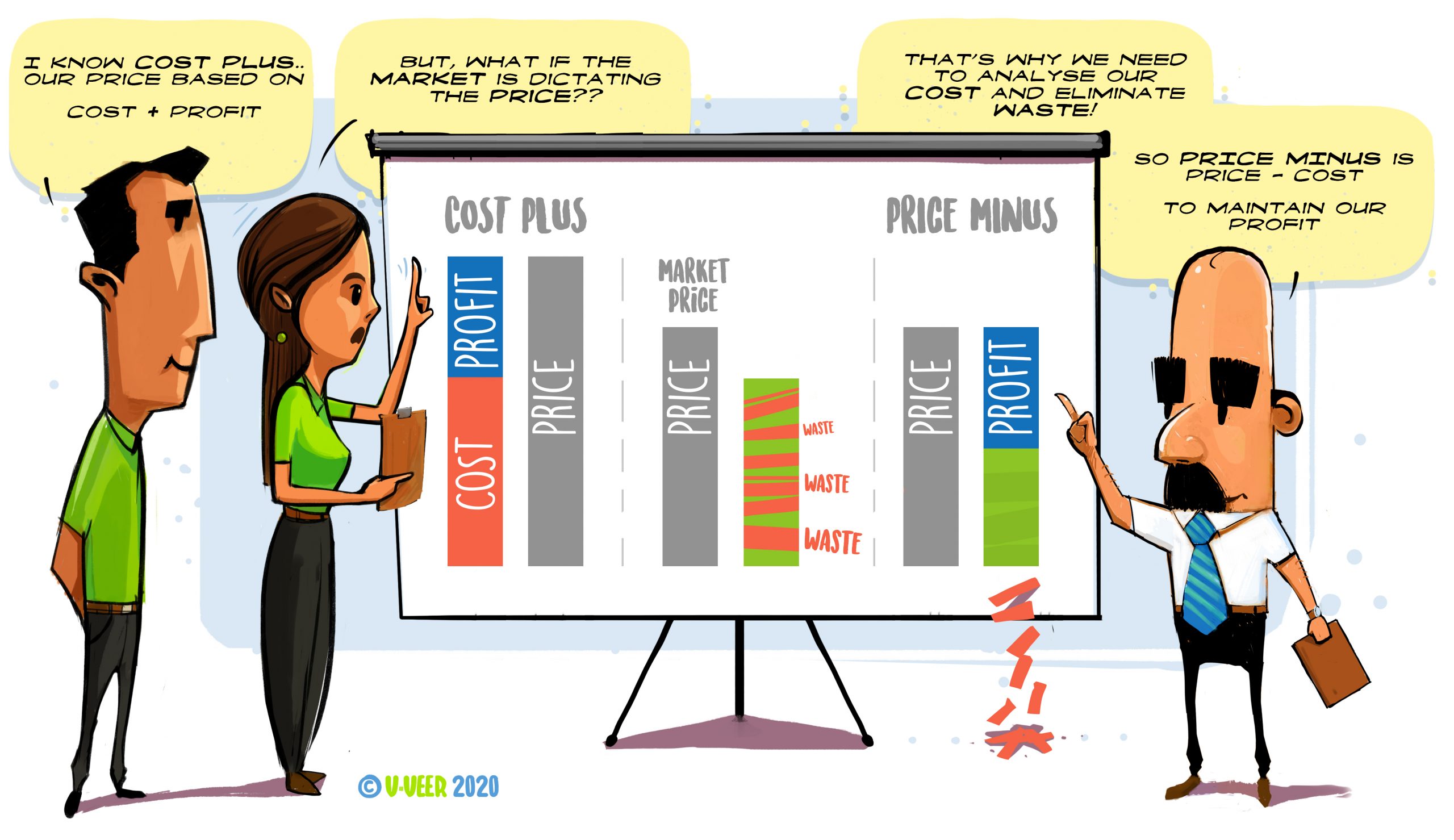

Calculating Profit

The traditional way of calculating profit is called ‘Profit Plus’. This is adding the profit margin to the actual cost to define the selling price. Lean thinking calculates profit by eliminating the waste in the cost and deducting it from the competitive sales price. This is called ‘Price Minus’.

Cost Plus: Price= Cost + Profit Price Minus: Profit= Price – Cost

Customer Satisfaction

To achieve customer satisfaction you need to focus on 3 elements quality, cost, and delivery.

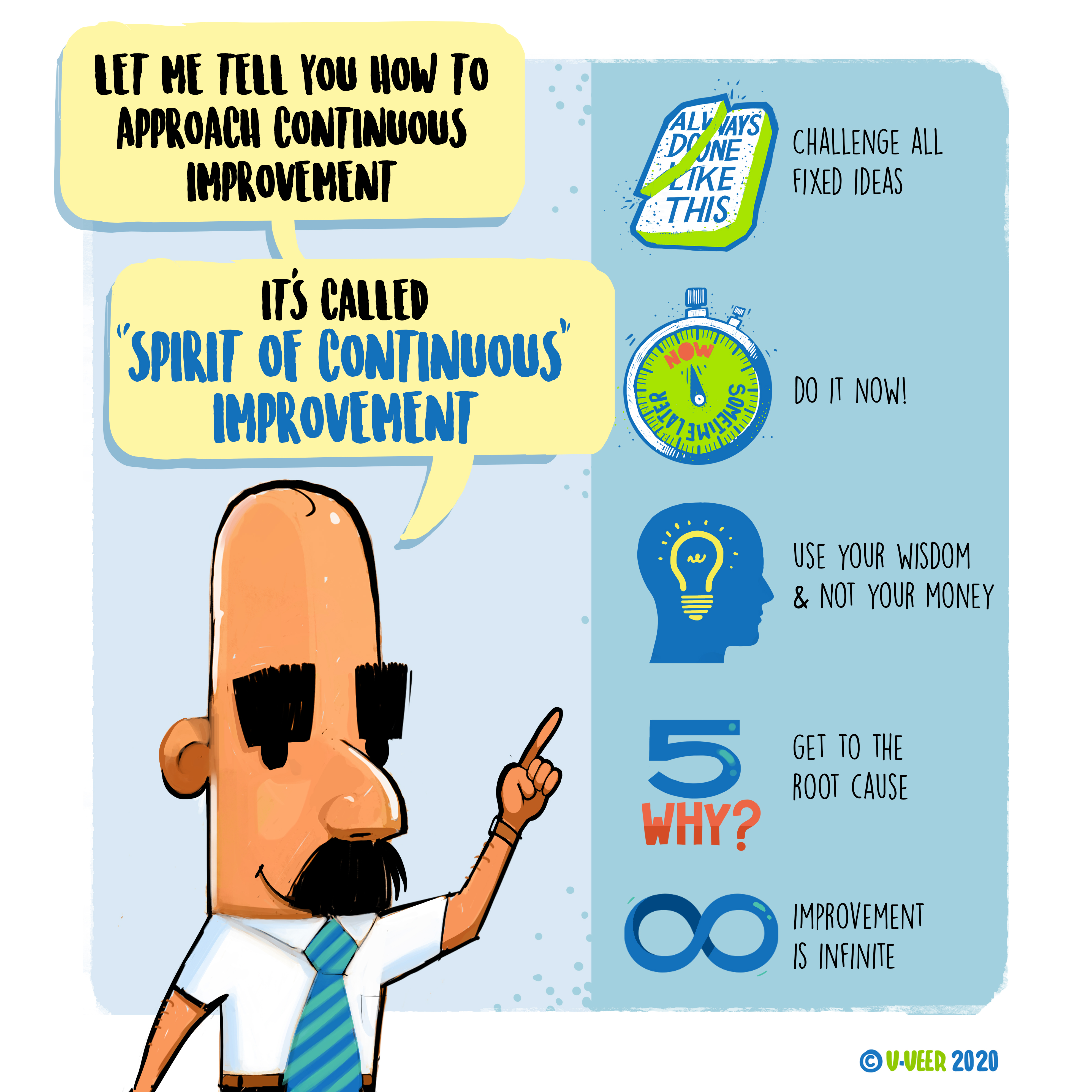

Continuous Improvement Spirit

Continuous improvement can be challenging on different levels. You need to approach it with the ‘Spirit of Continuous Improvement’. The 5 factors to continuous improvement spirit are challenge all fixed ideas, do it now, use your wisdom and not your money, get to the root cause, and improvement is infinite.

Kaizen Approach to Improve Productivity & Efficiency

To improve productivity and efficiency you need to work smarter not harder. The kaizen approach to improve productivity and efficiency is by eliminating waste.

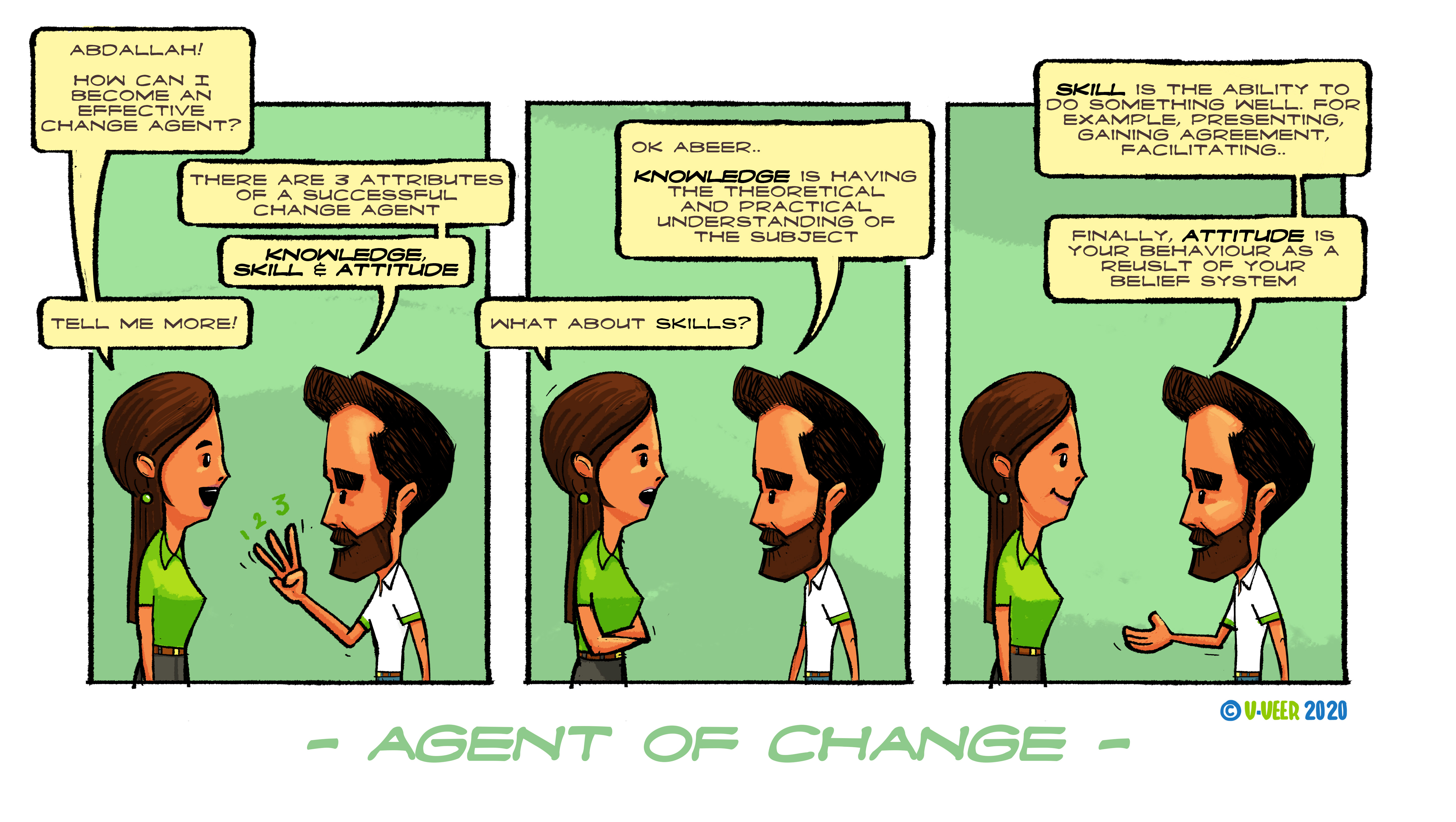

Change Agent Attributes

3 attributes of a successful change agent are Knowledge, Skills, Attitude.

Push vs. Pull

Move from a push to a pull system to have a stable process and calmer workforce.

Push System: Material is pushed to the next stage as soon as it has been processed.

Pull System: Material is produced only when the next stage wants it.

Production Mindset Change

Change your production mindset from forecasting to customer demand based. The first creates a mismatch between the actual produced quantity and the actual demand that results in complaining and blaming the customer. The lateral guarantees that the produced quantity meets the actual demand of the customer.

3M Mura, Muri, Muda

The 3M that has a negative impact on work are Mura, Muri, and Muda.

Mura: Un-evenness, Muri: Overburden, Muda: Waste

7 Wastes

Waste are activities that don’t add value from a customer point of view. There are 7 different types of waste. Eliminating the 7 wastes improves the work, reduces lead time, and enhances the work environment.

5S

5S is a 5 step technique to stabilise, maintain and improve the safest, best working environment to support sustainable QCD.

Visual Management

Visual management is a form of communication used to give information throughout operations and processes. Visual Management identifies normal and abnormal conditions as well as provokes a reaction.

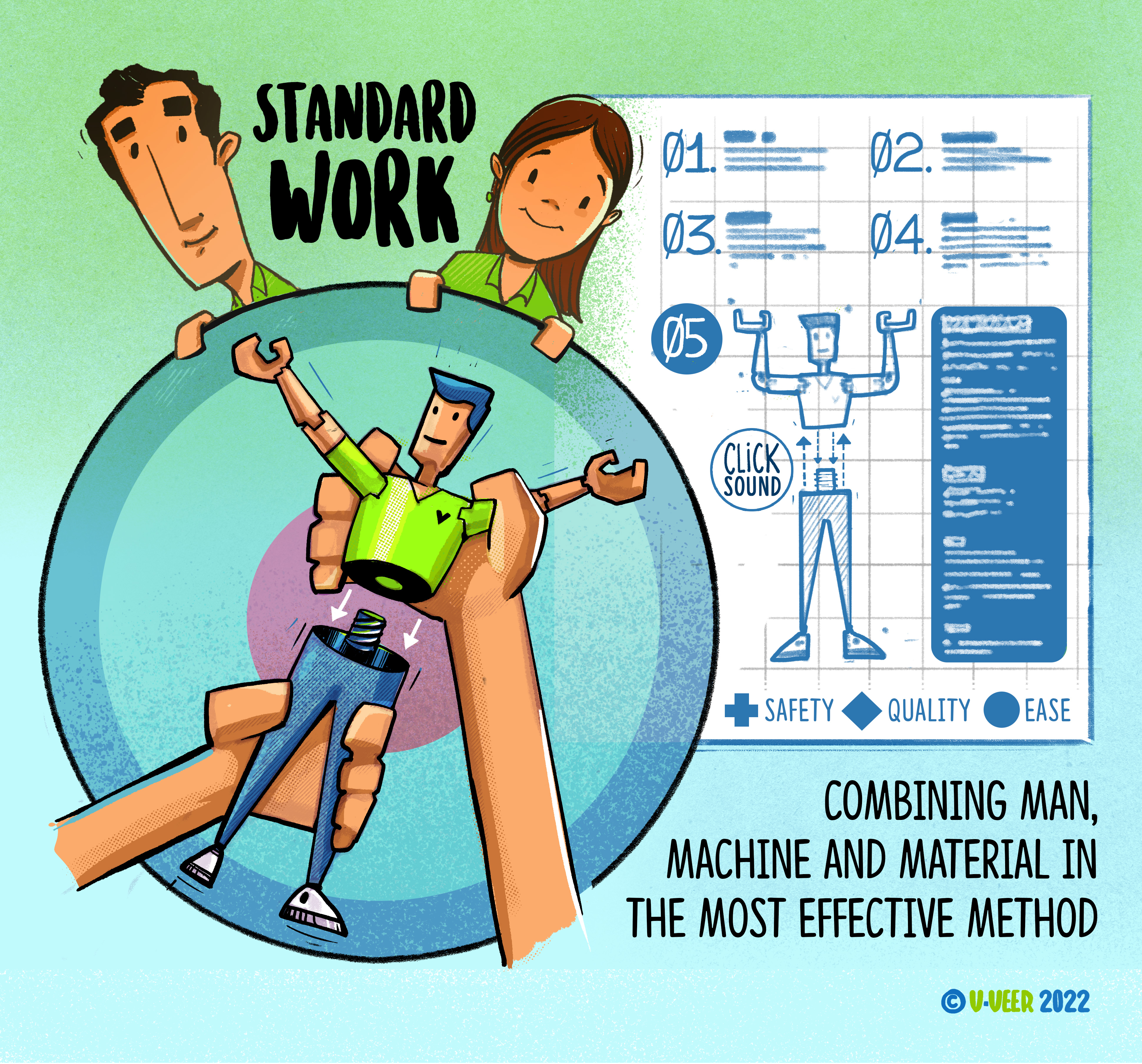

Standard Work

Standard Work is a means of establishing precise procedures to make products in the safest, easiest, and most effective way based on current technologies and formulas. It combines man, machine and material in the most effective method.

Tell, Show, Do

Tell, Show, Do is a 3 step method that incorporates a variety of ways to create effective, engaging learning experiences that guarantees mastering the task or job.